The Science behind BioNatur

BioNatur harnesses the power of scientific innovation to address the pressing challenge of plastic pollution. Through meticulous research and development, we've engineered plastics that biodegrade in anaerobic environments (including most landfills), offering a sustainable solution grounded in rigorous scientific principles.

Anaerobically Biodegradable

BioNatur Plastics are biodegradable in an anaerobic (lack of oxygen) environment. Current testing standard, ASTM D5511, demonstrates that our plastic biodegrades 99.7% in 1,697 days in the test environment. This particular test reflects a high heat and high moisture anaerobic environment, comparable to most landfills. While actual landfills may have less heat and less moisture compared to controlled test conditions, the presence of methane (a byproduct of anaerobic biodegradation) demonstrates that biodegradation does occur. Many U.S. landfills are capturing methane produced through biodegradation and converting it into energy—a trend that's steadily gaining momentum.

BioNatur's proprietary organic additive attracts naturally occurring anaerobic bacteria in a landfill to digest the additive and create enzymes that break down the large plastic polymers into smaller hydrocarbons that the bacteria then recognize as food. The bacteria then digest these smaller hydrocarbons into water, dirt and gases.

The Process

Testing

ASTM D5511 testing has shown up to 99.7% biodegradation in 1,697 days under anaerobic conditions. Total petroleum hydrocarbon testing demonstrates that no plastics were left in the system after the conclusion of ASTM D5511 testing. (Actual rates of biodegradation will vary dependent upon specific environmental conditions.)

Additive

BioNatur’s proprietary organic additive attracts naturally occurring anaerobic bacteria in a landfill to digest the additive and create enzymes that break down large plastic polymers, which the bacteria then recognize as food and digest into water, dirt and gases.

Read about our test results

Additive

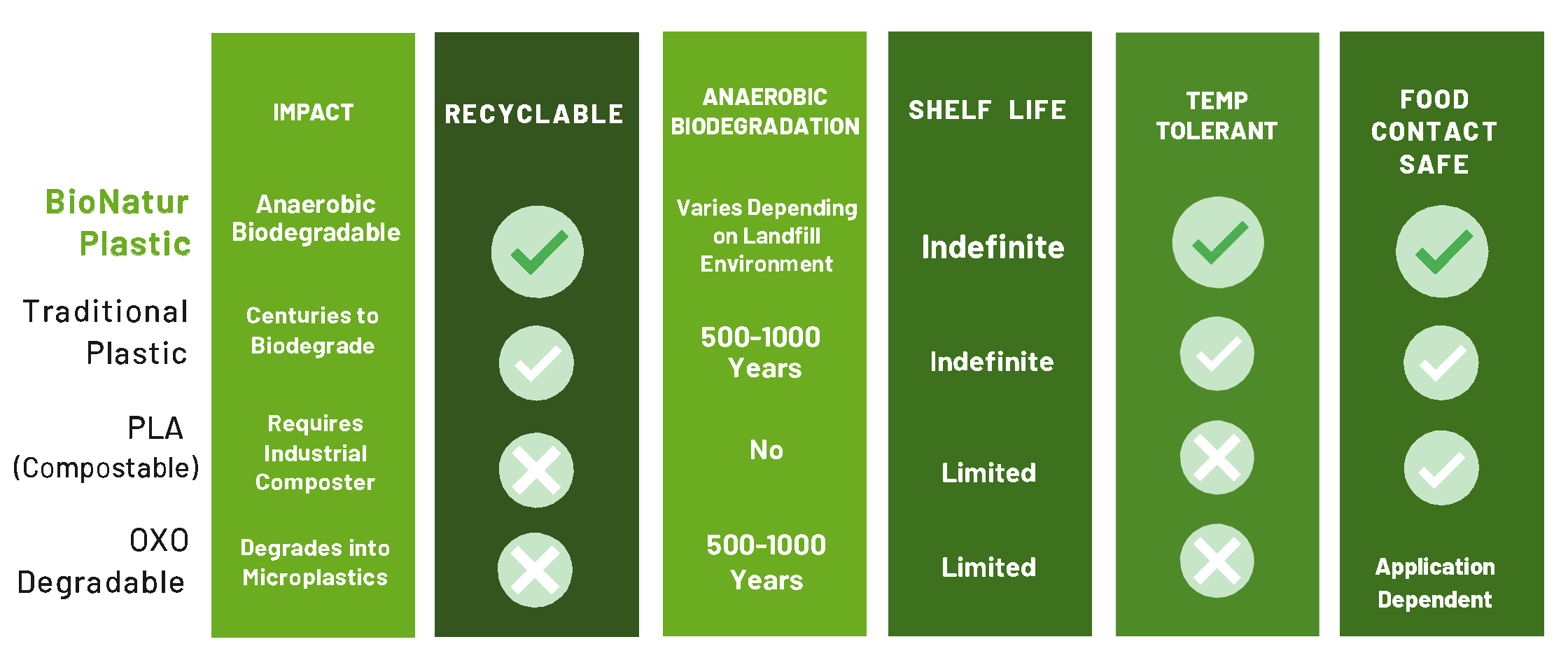

The BioNatur Difference

At BioNatur Plastics, we're not just another "biodegradable" plastic company. We strive to be transparent and demonstrate our results through testing. Our ASTM D5511 and residual hydrocarbon test results demonstrate that our plastics biodegrade under these rigorous lab conditions, and we can say with confidence that the anaerobic conditions present in most landfills will also digest our films. We recognize that conditions can vary greatly from landfill to landfill and that the time required to biodegrade can vary as well. Landfills that produce methane are actively undergoing anaerobic biodegradation and our test results confirm that our films are capable of biodegrading under those same conditions. Even better, they remain fully recyclable alongside standard low-density polyethylene wherever recycling programs accept it.

What about Oxodegradable?

Oxo-degradable plastics contain additives that cause them to fragment into smaller pieces when exposed to heat, light, or oxygen over time. While these smaller fragments may seem to disappear, they don't truly biodegrade into harmless substances and can persist in the environment as microplastics, posing potential risks to ecosystems and wildlife.

vs

Shelf Life

BioNatur's indefinite shelf life, akin to traditional plastics, ensures longevity without compromising on environmental responsibility. Unlike PLA or plastics containing oxo-biodegradable additives, BioNatur remains stable and does not disintegrate into harmful microplastics. Its unique biodegradation process in landfills occurs independent of heat, light, or oxygen, offering a sustainable alternative without sacrificing durability or performance.

anaerobically BIOdegradable

On the other hand, plastics like BioNatur, are designed to biodegrade in water, dirt and gases under anaerobic conditions which include those found in most landfills. Naturally occurring microorganisms are able to actively digest our plastics, reducing plastic waste and environmental impact and eliminating harmful microplastics.

Why This Matters

Degradable plastics simply break down into microparticles of plastic. This is why OXO-degradable plastic has been banned in the European Union.

The European Union directive on the reduction of the impact of certain plastic products on the environment became law in April 2019 and includes a ban on oxo-degradable plastics. (EU directive 2019/904 Article 5)

our technology is biodegradable in an anaerobic environment and recyclable where collected.

FAQs

-

Theoretically, any material made up of organic compounds is biodegradable. No matter how long it takes, the carbon-based material will inevitably decay into carbon dioxide and water via microbial respiration.

Biodegradable materials are materials that can be broken down naturally by microorganisms such as bacteria, fungi and algae. The degradation of these materials occurs through the consumption by bacteria to produce water, gasses, minerals, and new biomass over time. It is possible for these materials to biodegraded by anaerobic bacteria (in the absence of oxygen). Some of our competitors are blatantly wrong in their statements. We don’t know if they are lying, or if their salespeople honestly don’t understand the technology. If you read that “biodegradable means microplastics,” they are wrong.

BioNatur plastics are biodegradable in an anaerobic environment, including most landfills - where 86% of all plastic waste will end up. Our proprietary organic additive target microorganisms capable of processing petroleum molecules. It has been tested using ASTM D5511 standards to ensure our plastics biodegrade into water, dirt and gases. And total petroleum hydrocarbon testing demonstrates that no plastics were left in the system after the conclusion of ASTM D5511 testing.

BioNatur plastic uses an organic polymer to attract naturally occurring anaerobic bacteria in the landfill to digest the enzymes and break down the large plastic polymer molecules into smaller organic molecules that the bacteria then recognize as food. They then digest these smaller molecules and continue the process until the plastic is fully biodegraded in a fraction of the time it takes traditional plastic to biodegrade.

-

Degradation is a decomposition process that terminates in the fragmentation of plastics under the conditions of heat, sunlight, and moisture, resulting in the weakening of the plastic’s physical structure. So-called oxo-degradables are in this category. They often cite ASTM D6954 testing to make their claims.

Some of these oxo-degradable manufacturers claim that by breaking down the large piece of plastic in to microplastics, they can quicken the pace by which they are oxidized by bacteria into water and gasses. None that we have met to date can provide testing data to demonstrate this end-of-life condition.

The end product is many microscopic particles that may be even more problematic than before degradation as they may find their way into the diet of animal life and influence the food chain. Many experts have suggested that degradable plastics do not solve any problem but instead push the problem into the future, with the production of micro plastics. The European Union has banned oxo-degradable plastics for just this reason.

-

Degradable plastics simply break down into microparticles of plastic. This is why OXO-degradable plastic has been banned in the European Union.

The European Union directive on the reduction of the impact of certain plastic products on the environment became law in April 2019 and includes a ban on oxo-degradable plastics. (EU directive 2019/904 Article 5)

-

Compostable materials, like biodegradable materials, are broken down by microorganisms but with a key difference: The broken-down matter must enhance the nutritious quality of the soil without introducing any toxicity. Also, this entire process must take place within 12 weeks for a material to be considered compostable.

Commercially produced compostable products (such as the compostable cutlery, cups and plates used by many restaurants) need to be sent to an industrial composting facility in order to biodegrade, where adequate conditions (such as temperature, humidity, etc.) are maintained. They will not break down in a home compost pile or a landfill. ASTM D6400 testing will show if a product is compostable – but ONLY in an industrial composter.

Looking at the definitions of these terms it’s pretty understandable why they are so easily confused but there’s a difference: While all compostable material is biodegradable, not all biodegradable material is compostable.

Decoding plastics: What Sets Bionatur Apart?

Have an additional question or need additional help?